[nextpage title=”Introduction”]

Antec offers four power supply models within their High Current Pro (HCP) series: 750 W, 850 W, 1,000 W, and 1,200 W. The 1,000 W model has the 80 Plus Platinum certification, while the other models carry the 80 Plus Gold certification. Today we are going to take a look at the 750 W version, which features four +12 V rails. Let’s see if it is a good buy.

Units from the Antec High Current Pro series are manufactured by Delta Electronics.

Figure 1: Antec High Current Pro 750 W power supply

Figure 2: Antec High Current Pro 750 W power supply

The Antec High Current Pro 750 W is 7.1” (180 mm) deep, using a 135 mm ball-bearing fan on its bottom (ADDA ADN512UB-A9B).

Figure 3: Fan

The modular cabling system from this power supply has eight connectors: five red connectors for any kind of cable (including SATA and peripheral cables) and three black connectors specifically for SATA and peripheral power connectors. The unit comes with the main motherboard cable, an ATX12V/EPS12V cable, and one cable with connectors for video cards permanently attached to it. They use nylon sleeves that come from inside the unit. This power supply comes with the following cables:

- Main motherboard cable with a 20/24-pin connector, 21.6” (55 cm) long, permanently attached to the power supply

- One cable with two ATX12V connectors that together form an EPS12V connector, 25.6” (65 cm) long, permanently attached to the power supply

- One cable with one EPS12V connector, 25.6” (65 cm) long, modular cabling system

- One cable with two six/eight-pin connectors for video cards, 21.6” (55 cm) to the first connector, 5.9” (15 cm) between connectors, permanently attached to the power supply

- One cable with two six/eight-pin connectors for video cards, 21.6” (55 cm) to the first connector, 5.9” (15 cm) between connectors, modular cabling system

- Three cables, each with three SATA power connectors, 21.6” (55 cm) to the first connector, 5.9” (15 cm) between connectors, modular cabling system

- One cable with three standard peripheral power connectors, 21.6” (55 cm) to the first connector, 5.9” (15 cm) between connectors, modular cabling system

- One cable with three standard peripheral power connectors and one floppy disk drive power connector, 21.6” (55 cm) to the first connector, 5.9” (15 cm) between connectors, modular cabling system

All wires are 18 AWG, except for the wires on the main motherboard power cable and on the ATX12V/EPS12V that is permanently attached to the power supply, which are thicker (16 AWG).

The number of connectors is adequate for a 750 W power supply.

Figure 4: Cables

Let’s now take an in-depth look inside this power supply.

[nextpage title=”A Look Inside the Antec High Current Pro 750 W”]

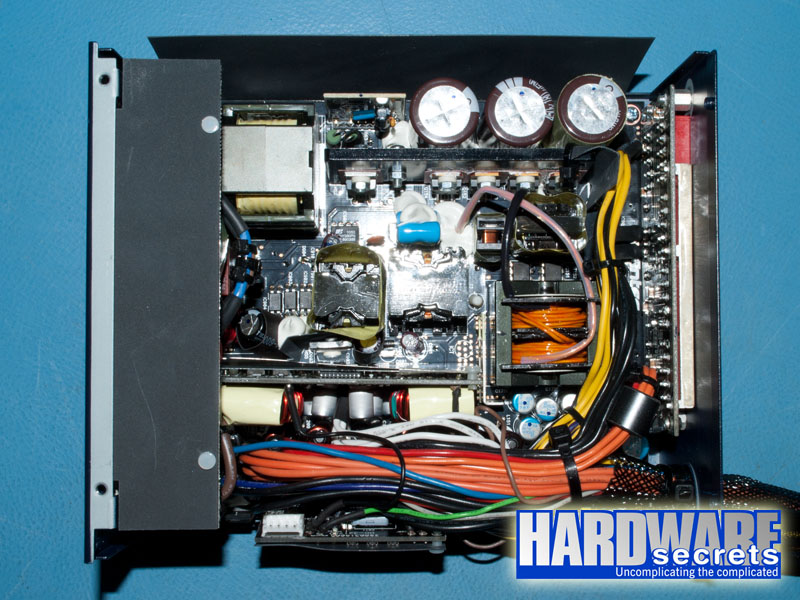

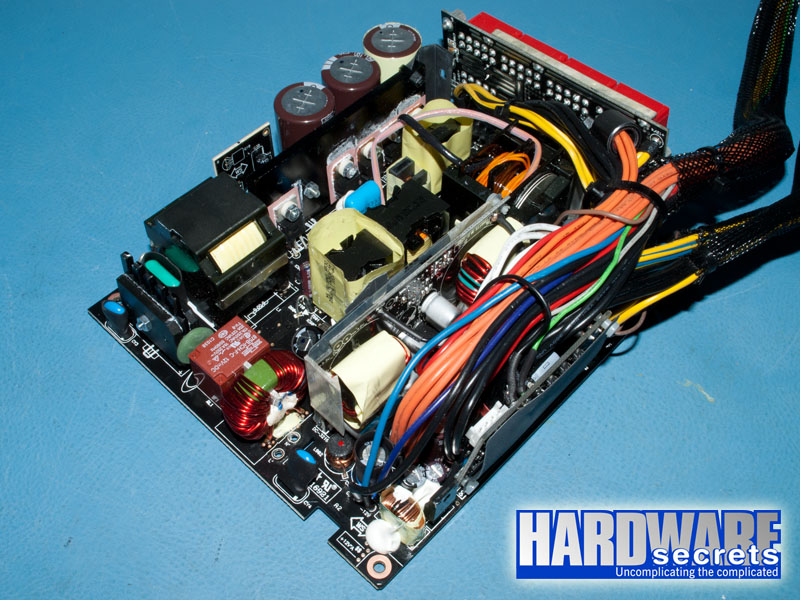

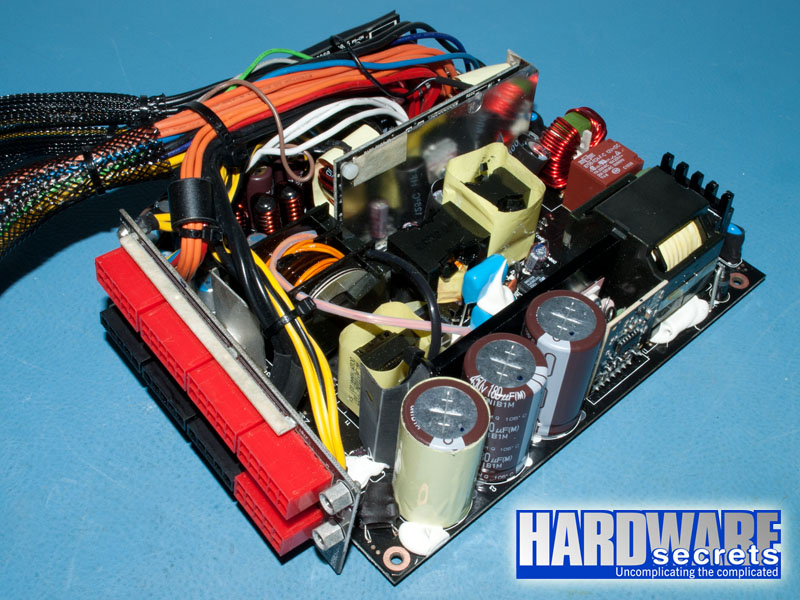

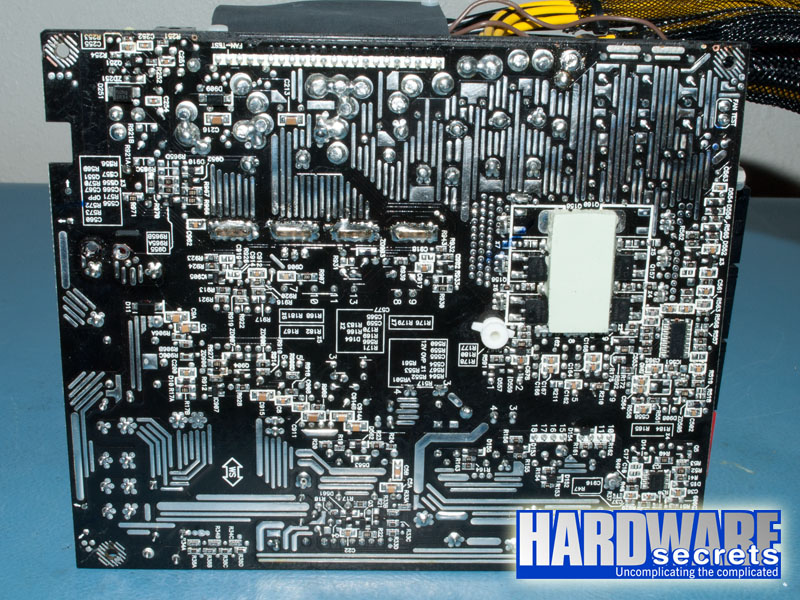

We decided to disassemble this power supply to see what it looks like inside, how it is designed, and what components are used. Please read our “Anatomy of Switching Power Supplies” tutorial to understand how a power supply works and to compare this power supply to others.

On this page we will have an overall look, and then in the following pages we will discuss in detail the quality and ratings of the components used.

Figure 5: Top view

Figure 6: Front quarter view

Figure 7: Rear quarter view

Figure 8: The printed circuit board

[nextpage title=”Transient Filtering Stage”]

As we have mentioned in other articles and reviews, the first place we look when opening a power supply for a hint about its quality, is its filtering stage. The recommended components for this stage are two ferrite coils, two ceramic capacitors (Y capacitors, usually blue), one metalized polyester capacitor (X capacitor), and one MOV (Metal-Oxide Varistor). Very low-end power supplies use fewer components, usually removing the MOV and the first coil.

In the transient filtering stage, this power supply is flawless, with one X capacitor, four Y capacitors, and one ferrite coil more than the minimum required. It also uses a CAPZero (CAP008DG) chip to reduce power loss.

Figure 9: Transient filtering stage (part 1)

Figure 10: Transient filtering stage (part 2)

Figure 11: Transient filtering stage (part 3)

Figure 12: The CAPZero chip

On the next page, we will have a more detailed discussion about the components used in the Antec High Current Pro 750 W.[nextpage title=”Primary Analysis”]

On this page, we will take an in-depth look at the primary stage of the Antec High Current Pro 750 W. For a better understanding, please read our “Anatomy of Switching Power Supplies” tutorial.

This power supply uses two D25XB60 rectifying bridges connected in parallel, which are attached to an individual heatsink. Each bridge supports up to 25 A at 98° C. In theory, you would be able to pull up to 5,750 W from a 115 V power grid. Assuming 80% efficiency, the bridges would allow this unit to deliver up to 4,600 W without burning themselves out (or 5,175 W at 90% efficiency). Of course, we are only talking about these particular components. The real limit will depend on all the components combined in this power supply.

Figure 13: Rectifying bridges

The active PFC circuit uses two IPP60R165F MOSFETs, each one supporting up to 21 A at 25° C or 13 A at 100° C in continuous mode (note the difference temperature makes), or 61 A at 25° C in pulse mode. These transistors present a 165 mΩ maximum resistance when turned on, a characteristic called RDS(on). The lower the number the better, meaning that the transistor will waste less power, and the power supply will have a higher efficiency.

Figure 14: The active PFC diode and one of the active PFC transistors

The active PFC circuit is managed by an FAN6982 active PFC controller.

Figure 15: Active PFC controller

The output of the active PFC circuit is filtered by three 180 µF x 450 V Japanese electrolytic capacitors, from Chemi-Con, labeled at 105° C. They are connected in parallel and are the equivalent of one 540 µF x 450 V capacitor.

Figure 16: Capacitors

In the switching section, four STP21NM60ND MOSFETs are employed using a full-bridge, resonant configuration. Each transistor supports up to 17 A at 25° C or 10 A at 100° C in continuous mode or up to 68 A at 25° C in pulse mode, with a maximum RDS(on) of 220 mΩ.

Figure 17: One of the active PFC transistors and the four switching transistors

The switching transistors are controlled by a CM6901 controller.

Figure 18: Resonant controller

Let’s now take a look at the secondary of this power supply.[nextpage title=”Secondary Analysis”]

As one would expect in a high-efficiency power supply, the Antec High Current Pro 750 W uses a synchronous design, where the Schottky rectifiers are replaced with MOSFETs. Also, the reviewed product uses a DC-DC design in its secondary. This means that the power supply is basically a +12 V unit, with the +5 V and +3.3 V outputs produced by two smaller power supplies connected to the main +12 V rail. Both designs are used to increase efficiency.

The +12 V output uses four IPD031N06L3 G MOSFETs, each one supporting up to 100 A at 100° C in continuous mode, or up to 400 A at 25° C in pulse mode, with a maximum RDS(on) of 3.1 mΩ. These transistors are located on the solder side of the printed circuit board and use the power supply case as their heatsink.

Figure 19: The +12 V transistors

As explained, the +5 V and +3.3 V outputs are produced by two DC-DC converters, which are situated on a single printed circuit board located in the secondary section of the power supply. The converters are controlled by an APW7159 integrated circuit. The +3.3 V converter uses four AOD4132 MOSFETS, while the +5 V converter uses another three. Each transistor supports up to 85 A at 25° C or 63 A at 100° C in continuous mode and up to 200 A at 25° C in pulse mode, with a maximum RDS(on) of 6 mΩ.

Figure 20: The DC-DC converters

Figure 21: The DC-DC converters

The outputs of the power supply are monitored by a DWA103N integrated circuit. Unfortunately, the datasheet for this chip is not available.

Figure 22: Mon

itoring circuit

The electrolytic capacitors available in the secondary are also Japanese, from Chemi-Con and Rubycon, and labeled at 105° C, as usual. As you can see in Figure 23, several solid capacitors are also used.

Figure 23: Capacitors

[nextpage title=”Power Distribution”]

In Figure 24, you can see the power supply label containing all the power specs.

Figure 24: Power supply label

According to the manufacturer, this unit has four +12 V rails. These rails are distributed as follows:

- +12V1 (solid yellow wires): The motherboard main connector and the SATA and peripheral connectors from the modular cabling system

- +12V2 (yellow/black wires): The ATX12V/EPS12V connector that is permanently attached to the power supply and the red connector that is close to the black connectors on the modular cabling system

- +12V3 (yellow/blue wires): The video card power connector that is permanently attached to the power supply and two of the red connectors on the modular cabling system

- +12V4 (yellow/purple wires): The remaining two red connectors on the modular cabling system

This distribution is perfect, and luckily, the manufacturer labeled the rails on the modular cabling system.

How much power can this unit really deliver? Let’s find out.

[nextpage title=”Load Tests”]

We conducted several tests with this power supply, as described in the article, “Hardware Secrets Power Supply Test Methodology.”

First, we tested this power supply with five different load patterns, trying to pull around 20%, 40%, 60%, 80%, and 100% of its labeled maximum capacity (actual percentage used listed under “% Max Load”), watching the behavior of the reviewed unit under each load. In the table below, we list the load patterns we used and the results for each load.

If you add all the powers listed for each test, you may find a different value than what is posted under “Total” below. Since each output can have a slight variation (e.g., the +5 V output working at 5.10 V), the actual total amount of power being delivered is slightly different than the calculated value. In the “Total” row, we are using the real amount of power being delivered, as measured by our load tester.

The +12VA and +12VB inputs listed below are the two +12 V independent inputs from our load tester. During this test, the +12VA input was connected to the power supply +12V1 and +12V3 rails, while the +12VB input was connected to the power supply +12V2 rail.

| Input | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 |

| +12VA | 5.5 A (66 W) | 11 A (132 W) | 16.5 A (198 W) | 21.5 A (258 W) | 27.5 A (330 W) |

| +12VB | 5.5 A (66 W) | 11 A (132 W) | 16 A (192 W) | 21.5 A (258 W) | 27.5 A (330 W) |

| +5 V | 1 A (5 W) | 2 A (10 W) | 4 A (20 W) | 6 A (30 W) | 8 A (40 W) |

| +3.3 V | 1 A (3.3 W) | 2 A (6.6 W) | 4 A (13.2 W) | 6 A (19.8 W) | 8 A (26.4 W) |

| +5VSB | 1 A (5 W) | 1.5 A (7.5 W) | 2 A (10 W) | 2.5 A (12.5 W) | 3 A (15 W) |

| -12 V | 0.5 A (6 W) | 0.5 A (6 W) | 0.5 A (6 W) | 0.5 A (6 W) | 0.5 A (6 W) |

| Total | 141.1 W | 297.4 W | 441.0 W | 584.4 W | 746.4 W |

| % Max Load | 18.8% | 39.7% | 58.8% | 77.9% | 99.5% |

| Room Temp. | 47.0° C | 46.7° C | 47.2° C | 44.2° C | 45.8° C |

| PSU Temp. | 52.3° C | 52.2° C | 52.7° C | 52.8° C | 55.0° C |

| Voltage Regulation | Pass | Pass | Pass | See Text | See Text |

| Ripple and Noise | Pass | Pass | Pass | Pass | Pass |

| AC Power | 164.9 W | 333.8 W | 496.3 W | 662.0 W | 855.0 W |

| Efficiency | 85.6% | 89.1% | 88.9% | 88.3% | 87.3% |

| AC Voltage | 114.9 V | 112.7 V | 111.0 V | 109.4 V | 107.2 V |

| Power Factor | 0.988 | 0.99 | 0.996 | 0.998 | 0.998 |

| Final Result | Pass | Pass | Pass | Fail | Fail |

The 80 Plus Gold certification guarantees minimum efficiencies of 87% at 20% load, 90% at 50% load, and 87% at 100% load. However, in our tests, the Antec High Current Pro 750 W presented 86.5% efficiency at 20% load. We didn’t test this power supply at 50% load, but considering that we saw 89.1% efficiency at 40% load and 88.9% efficiency at 60% load, it may be possible that this unit is able to achieve 90% efficiency at 50% load. At full load, we saw 87.3% efficiency. Always keep in mind that we test power supplies between 45° C and 50° C, while the 80 Plus tests are conducted at 23° C, and efficiency drops as temperature increases.

The main problem with this power supply during our tests, however, was voltage regulation. With the first sample we received, the +3.3 V output dropped to +3.07 V when we pulled 750 W from this unit. On the other hand, all other outputs were within 3% of their nominal value during all tests, except the +3.3 V output during test four (at +3.18 V) and +5VSB at test five (at +4.85 V).

Considering that we might have received a defective sample, we requested a second sample from Antec. The +3.3 V output of the second sample was always within 3% of its nominal value; however, now the +5VSB output was the one that dropped below the minimum allowed, at +4.65 V during test four and at +4.59 V during test five. This output was within 3% of its nominal value during test one; but at test two, it dropped to +4.84 V; and at test three, it dropped to +4.77 V. All other outputs were within 3% of their nominal values.

Since we test power supplies at high temperatures, we wondered if this problem was not being caused by high temperature. We let the power supply cool down and retested the samples at 25° C, with the same results.

Antec sent us a third sample of this power supply, which finally passed our voltage regulation tests. With this sample, all voltages were closer to their nominal values than required (3% regulation), except the +5VSB output during test five, which was at +4.81 V, still inside the allowed range.

The ATX12V specification states that positive voltages must be within 5% of their nominal values, and negative voltages must be within 10% of their nominal values.

Let’s discuss the ripple and noise levels on the next page.

[nextpage title=”Ripple and Noise Tests”]

Voltages at the power supply outputs must be as “clean” as possible, with no noise or oscillation (also known as “ripple”). The maximum ripple and noise levels allowed are 120 mV for +12 V and -12 V outputs, and 50 mV for +5 V, +3.3 V and +5VSB outputs. All values are peak-to-peak figures. We consider a power supply as

being top-notch if it can produce half or less of the maximum allowed ripple and noise levels.

The Antec High Current Pro 750 W provided very low ripple and noise levels, as you can see in the table below.

| Input | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 |

| +12VA | 23.0 mV | 42.2 mV | 33.8 mV | 33.2 mV | 35.4 mV |

| +12VB | 27.0 mV | 44.0 mV | 34.8 mV | 33.2 mV | 34.4 mV |

| +5 V | 10.2 mV | 17.4 mV | 16.0 mV | 13.6 mV | 11.8 mV |

| +3.3 V | 13.2 mV | 19.4 mV | 25.2 mV | 31.4 mV | 23.4 mV |

| +5VSB | 19.2 mV | 18.0 mV | 18.6 mV | 20.4 mV | 19.2 mV |

| -12 V | 72.4 mV | 71.8 mV | 71.8 mV | 71.4 mV | 73.2 mV |

Below you can see the waveforms of the outputs during test five.

Figure 25: +12VA input from load tester during test five at 746.4 W (35.4 mV)

Figure 26: +12VB input from load tester during test five at 746.4 W (34.4 mV)

Figure 27: +5V rail during test five at 746.4 W (11.8 mV)

Figure 28: +3.3 V rail during test five at 746.4 W (23.4 mV)

Let’s see if we can pull more than 650 W from this unit.

[nextpage title=”Overload Tests”]

Below you can see the maximum we could pull from this power supply. The objective of this test is to see if the power supply has its protection circuits working properly. This unit passed this test, since it shut down when we tried to pull more than what is listed below. During this test, noise and ripple levels were still low. With the first sample, the +3.3 V output dropped even further, to +3.02 V. Using the second sample, the +5VSB output also dropped even more, to +4.54 V. All other outputs remained within 3% of their nominal values, except for the first sample, where the +5VSB output was at +4.82 V, and still within the proper range. With the third sample, the +3.3 V output was at +3.05 V and the +5VSB output was at +4.72 V, both below the minimum allowed. The other outputs were within 3% of their nominal values.

| Input | Overload Test |

| +12VA | 33 A (396 W) |

| +12VB | 33 A (396 W) |

| +5 V | 14 A (70 W) |

| +3.3 V | 14 A (46.2 W) |

| +5VSB | 3 A (15 W) |

| -12 V | 0.5 A (6 W) |

| Total | 875.4 W |

| % Max Load | 116.7% |

| Room Temp. | 44.8° C |

| PSU Temp. | 54.8° C |

| AC Power | 1,033 W |

| Efficiency | 84.7% |

| AC Voltage | 105.6 V |

| Power Factor | 0.999 |

[nextpage title=”Main Specifications”]

The main specifications for the Antec High Current Pro 750 W power supply include:

- Standards: ATX12V 2.3 and EPS12V 2.92

- Nominal labeled power: 750 W

- Measured maximum power: 875.4 W at 44.8° C

- Labeled efficiency: Up to 92%, 80 Plus Gold certification

- Measured efficiency: Between 85.6% and 89.1%, at 115 V (nominal, see complete results for actual voltage)

- Active PFC: Yes

- Modular Cabling System: Yes

- Motherboard Power Connectors: One 20/24-pin connector and two ATX12V connectors that together form an EPS12V connector, permanently attached to the power supply, and one EPS12V connector on the modular cabling system

- Video Card Power Connectors: Two six/eight-pin connectors on one cable permanently attached to the power supply and two six/eight-pin connectors on one cable on the modular cabling system

- SATA Power Connectors: Nine on three cables, modular cabling system

- Peripheral Power Connectors: Six on two cables, modular cabling system

- Floppy Disk Drive Power Connectors: One

- Protections (as listed by the manufacturer): Over voltage (OVP), over current (OCP), over power (OPP), over temperature (OTP), and short-circuit (SCP) protections

- Are the above protections really available? Yes.

- Warranty: Five years

- Real Manufacturer: Delta Electronics

- More Information: https://www.antec.com

- Average Price in the U.S.*: USD 170.00

* Researched at Newegg.com on the day we published this review.[nextpage title=”Conclusions”]

Unfortunately, there is something going on with Antec’s quality control. The first two samples from the Antec High Current Pro 750 W we received provided voltages below the minimum allowed. While with the first sample it was the +3.3 V output that failed, with the second sample it was the +5VSB output that failed. We retested them at a lower temperature (25° C) with the same results. Only after receiving a third sample we got satisfactory results, with all voltages closer to their nominal values than required (3% voltage regulation).

Also, at USD 170, the Antec High Current Pro 750 W is more expensive than its competitors. There are better 750 W power supplies with the 80 Plus Gold and even 80 Plus Platinum certifications around costing a little less. A few examples include the Azza Platinum 750 W (USD 160), Seasonic X-750 (USD 160), and SilverStone Strider Gold Evolution 750 W (USD 165), just to name a few.

Leave a Reply