[nextpage title=”Introduction”]

The AK6 is the latest power supply series from 3R System, offered in two wattages, 500 W and 600 W, with (models ended with “M”) or without a modular cabling system. They come with the 80 Plus Bronze certification. We’ve already reviewed the 500 W model, which deserved our recommendation. Let’s now test the 600 W model with a modular cabling system, which the manufacturer promises a peak wattage of 700 W.

Figure 1: 3R System AK6-600M power supply

Figure 1: 3R System AK6-600M power supply

Figure 2: 3R System AK6-600M power supply

Figure 2: 3R System AK6-600M power supply

The 3R System AK6-600M is 6.3” (160 mm) deep, using a 120 mm sleeve bearing fan on its bottom (Yate Loon D12SM-12).

The modular cabling system from this power supply has six connectors. The product comes with only four cables to be installed on them, so two connectors are left unused. Differently from most modular cabling systems, the connectors can be used by any kind of cable; the unit doesn’t have special connectors for the video card power cables. The motherboard cables are permanently attached to the unit, and they have nylon sleeves, which come from inside the unit. This power supply comes with the following cables:

- Main motherboard cable with a 20/24-pin connector, 19.7” (50 cm) long, permanently attached to the power supply

- One cable with two ATX12V connectors that together form an EPS12V connector, 23.6” (60 cm) long, permanently attached to the power supply

- Two cables, each with one six/eight-pin connector for video cards, 17.7” (45 cm) long, modular cabling system

- One cable with three SATA power connectors, 17.7” (45 cm) to the first connector, 5.9” (15 cm) between connectors, modular cabling system

- One cable with three standard peripheral power connectors and one floppy disk drive power connector, 19.7” (50 cm) to the first connector, 5.9” (15 cm) between connectors, modular cabling system

All wires are 18 AWG, which is the minimum recommended gauge.

The cable configuration is identical to the one used by the 500 W model. We think this unit should have come with at least one other cable with three SATA power connectors, as the number of SATA power connectors is low for a 600 W unit.

Let’s now take an in-depth look inside this power supply.

[nextpage title=”A Look Inside the 3R System AK6-600M”]

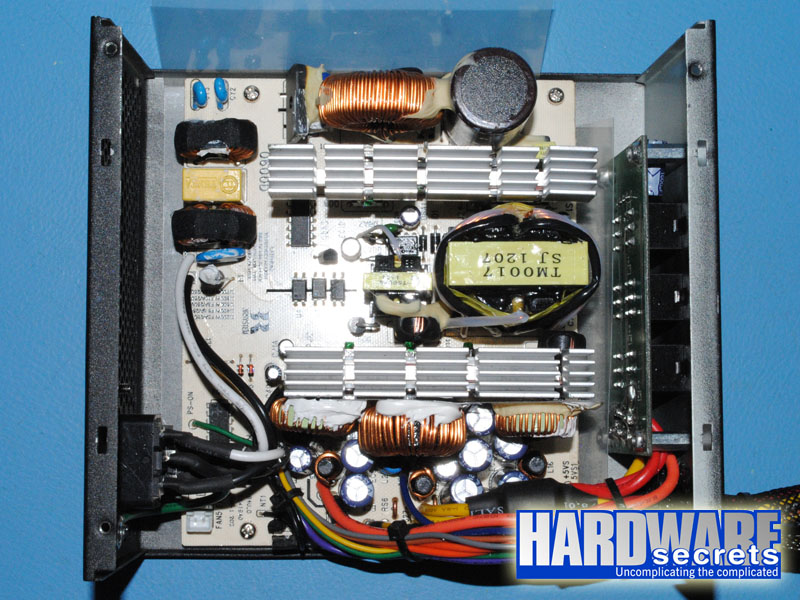

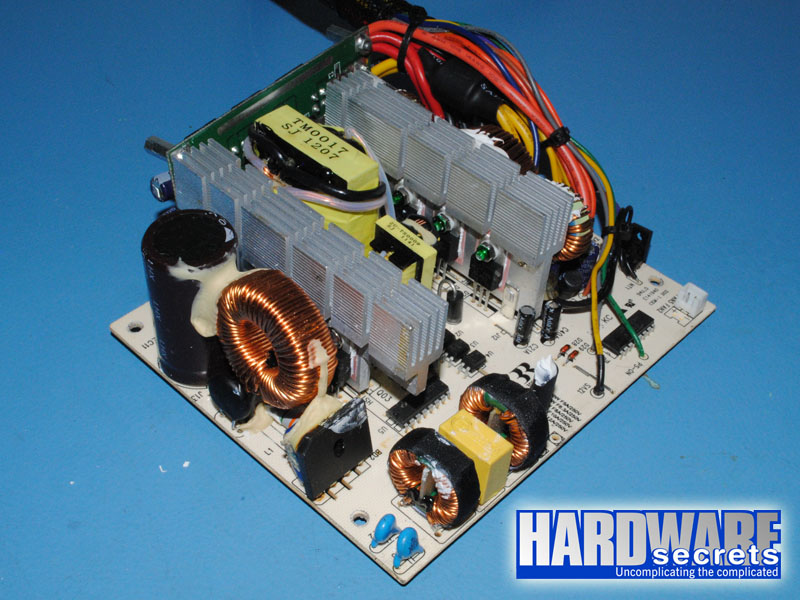

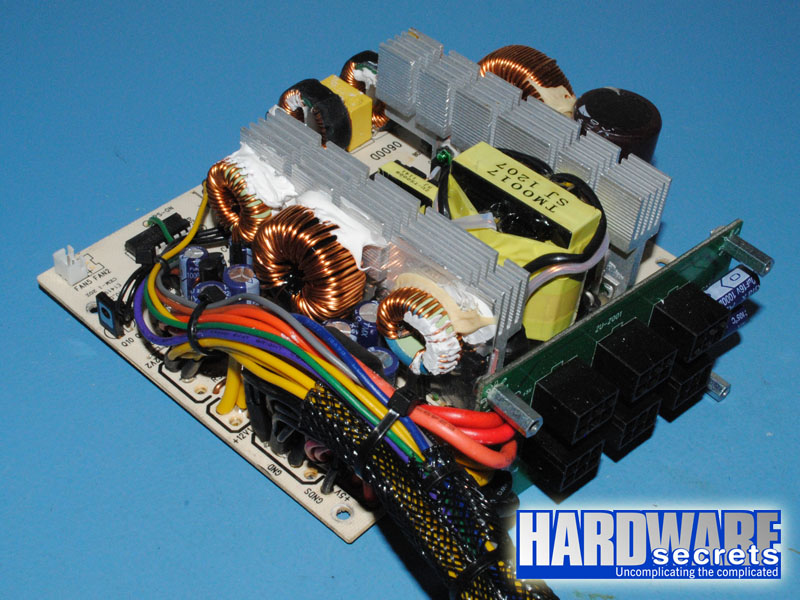

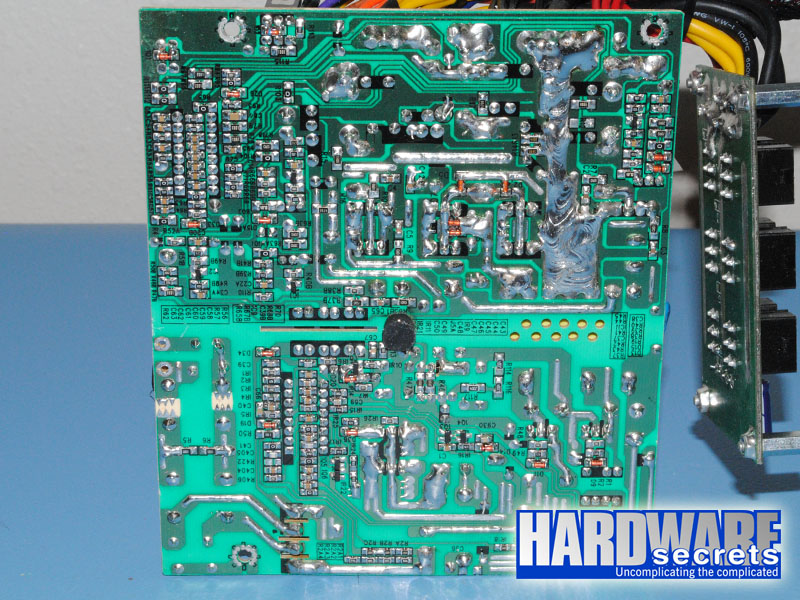

We decided to disassemble this power supply to see what it looks like inside, how it is designed, and what components are used. Please read our “Anatomy of Switching Power Supplies” tutorial to understand how a power supply works and to compare this power supply to others.

On this page we will have an overall look, and then in the following pages we will discuss in detail the quality and ratings of the components used.

Figure 4: Top view

Figure 4: Top view

Figure 5: Front quarter view

Figure 5: Front quarter view

Figure 6: Rear quarter view

Figure 6: Rear quarter view

Figure 7: The printed circuit board

Figure 7: The printed circuit board

[nextpage title=”Transient Filtering Stage”]

As we have mentioned in other articles and reviews, the first place we look when opening a power supply for a hint about its quality, is its filtering stage. The recommended components for this stage are two ferrite coils, two ceramic capacitors (Y capacitors, usually blue), one metalized polyester capacitor (X capacitor), and one MOV (Metal-Oxide Varistor). Very low-end power supplies use fewer components, usually removing the MOV and the first coil.

In the transient filtering stage, this power supply is flawless, with all of the required components.

Figure 8: Transient filtering stage

Figure 8: Transient filtering stage

On the next page, we will have a more detailed discussion about the components used in the 3R System AK6-600M.

[nextpage title=”Primary Analysis”]

On this page we will take an in-depth look at the primary stage of the Thortech Thunderbolt 850 W. For a better understanding, please read our “Anatomy of Switching Power Supplies” tutorial.

This power supply uses one U15K80R rectifying bridge, which isn’t attached to a heatsink. Unfortunately, we couldn’t find the exact datasheet for this bridge, but we can assume it is a 15 A component. (The real limit is lower, as this bridge isn’t attached to a heatsink.) In theory, you would be able to pull up to 1,725 W from a 115 V power grid. Assuming 80% efficiency, the bridge would allow this unit to deliver up to 1,380 W without burning itself out. Of course, we are only talking about this particular component. The real limit will depend on all the components combined in this power supply. This is the same bridge used in the 500 W model.

The active PFC circuit uses two SPP20N60C3 MOSFETs, each one supporting up to 20.7 A at 25° C or 13.1 A at 100° C in continuous mode (note the difference temperature makes), or 62.1 A at 25° C in pulse mode. These transistors present a 190 mΩ resistance when turned on, a characteristic called RDS(on).

The lower the number the better, meaning that the transistor will waste less power, and the power supply will have a higher efficiency. This is the same configuration used in the 500 W model.

The output of the active PFC circuit is filtered by one 330 µF x 400 V electrolytic capacitor from Asia’x, labeled at 105° C. The 500 W model uses a 270 µF x 400 V capacitor here.

In the switching section, another two SPP20N60C3 MOSFETs are employed using the traditional two-transistor forward configuration. The specifications for these transistors were already discussed above. This is the same configuration used in the 500 W model.

Figure 10: One of the active PFC transistors and the switching transistors

Figure 10: One of the active PFC transistors and the switching transistors

The primary is managed by a CM6802 active PFC/PWM combo controller.

Figure 11: Active PFC/PWM combo controller

Figure 11: Active PFC/PWM combo controller

Let’s now take a look at the secondary of this power supply.

[nextpage title=”Secondary Analysis”]

The 3R System AK6-600M uses a regular design in its secondary, with Schottky rectifiers.

The maximum theoretical current that each line can deliver is given by the formula I / (1 – D) where D is the duty cycle used and I is the maximum current supported by the rectifying diode. As an exercise, we can assume a duty cycle of 30 percent.

The +12 V output uses three PFR20L60CT Schottky rectifiers, each one supporting up to 20 A (10 A per internal diode at 120° C with a 0.65 V maximum voltage drop), and one IRFB3207 MOSFET, which supports up to 180 A at 25° C or 130 A at 100° C in continuous mode or up to 720 A at 25° C in pulse mode, with a maximum RDS(on) of only 4.5 mΩ. The 500 W model uses four PFR20L60CT rectifiers, so the 600 W model was upgraded by replacing one of them with a high-power MOSFET.

The +5 V output uses one PFR40L45PT Schottky rectifier, which supports up to 40 A (20 A per internal diode). Unfortunately, we couldn’t find its datasheet. This gives us a maximum theoretical current of 29 A or 143 W for the +5 V output. This is the same configuration used in the 500 W model.

The +3.3 V output uses two PFR30L45CT Schottky rectifiers, each one supporting up to 30 A (15 A per internal diode at 110° C with a 0.52 V maximum voltage drop). This gives us a maximum theoretical current of 43 A or 141 W for the +3.3 V output. This is the same configuration used in the 500 W model.

Figure 12: One of the +3.3 V rectifiers, two of the +12 V rectifiers, and the +5 V rectifier

Figure 12: One of the +3.3 V rectifiers, two of the +12 V rectifiers, and the +5 V rectifier

Figure 13: One of the +12 V rectifiers, the +12 V MOSFET, and one of the +3.3 V rectifiers

Figure 13: One of the +12 V rectifiers, the +12 V MOSFET, and one of the +3.3 V rectifiers

This power supply uses a GR8323 monitoring integrated circuit, which supports over voltage (OVP), under voltage (UVP), and over current (OCP) protections. There are two +12 V over current channels, correctly matching the number of +12 V rails announced by the manufacturer.

The electrolytic capacitors that filter the outputs are from Asia’x and labeled at 105° C, as usual.

In summary, the 600 W model is identical to the 500 W model, with only two major modifications: an electrolytic capacitor with higher capacitance in the primary and the replacement of one of the +12 V rectifiers with a MOSFET.

[nextpage title=”Power Distribution”]

In Figure 15, you can see the power supply label containing all the power specs.

According to the label, this unit has two +12 V rails. Inside the unit, we could clearly see two “shunts” (current sensors), one for each +12 V rail. The monitoring circuit really has two +12 V over current protection channels. Click here to understand more about this subject.

The two +12 V rails are distributed as follows:

- +12V1: The cables attached to the modular cabling system

- +12V2: The cables permanently attached to the power supply

Usually, on power supplies with two +12 V rails, one rail is dedicated to the ATX12V/EPS12V connector. However, on this power supply, the manufacturer added the main power supply connector to the same rail, which is fine.

How much power can this unit really deliver? Let’s find out.

[nextpage title=”Load Tests”]

We conducted several tests with this power supply, as described in the article, “Hardware Secrets Power Supply Test Methodology.”

First we tested this power supply with five different load patterns, trying to pull around 20%, 40%, 60%, 80%, and 100% of its labeled maximum capacity (actual percentage used listed under “% Max Load”), watching the behavior of the reviewed unit under each load. In the table below, we list the load patterns we used and the results for each load.

If you add all the powers listed for each test, you may find a different value than what is posted under “Total” below. Since each output can have a slight variation (e.g., the +5 V output working at +5.10 V), the actual total amount of power being delivered is slightly different than the calculated value. In the “Total” row, we are using the real amount of power being delivered, as measured by our load tester.

The +12VA and +12VB inputs listed below are the two +12 V independent inputs from our load tester. During this test, the

+12VA input was connected to the power supply +12V1 and +12V2 rails, while the +12VB input was connected to the power supply +12V2 rail.

| Input | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 |

| +12VA | 4 A (48 W) | 9 A (108 W) | 13 A (156 W) | 17.5 A (210 W) | 21.5 A (258 W) |

| +12VB | 4 A (48 W) | 9 A (108 W) | 13 A (156 W) | 17.5 A (210 W) | 21 A (252 W) |

| +5 V | 1 A (5 W) | 2 A (10 W) | 4 A (20 W) | 6 A (30 W) | 8 A (40 W) |

| +3.3 V | 1 A (3.3 W) | 2 A (6.6 W) | 4 A (13.2 W) | 6 A (19.8 W) | 8 A (26.4 W) |

| +5VSB | 1 A (5 W) | 1 A (5 W) | 1.5 A (7.5 W) | 2 A (10 W) | 3 A (15 W) |

| -12 V | 0.5 A (6 W) | 0.5 A (6 W) | 0.5 A (6 W) | 0.5 A (6 W) | 0.5 A (6 W) |

| Total | 116.3 W | 245.3 W | 360.8 W | 487.4 W | 603.4 W |

| % Max Load | 19.4% | 40.9% | 60.1% | 81.2% | 100.6% |

| Room Temp. | 45.8° C | 45.9° C | 47.1° C | 49.4° C | 48.0° C |

| PSU Temp. | 46.8° C | 46.7° C | 47.0° C | 48.4° C | 47.1° C |

| Voltage Regulation | Pass | Pass | Pass | Pass | Pass |

| Ripple and Noise | Pass | Pass | Pass | Pass | Pass |

| AC Power | 138.0 W | 284.7 W | 424.7 W | 591.5 W | 754.0 W |

| Efficiency | 84.3% | 86.2% | 85.0% | 82.4% | 80.0% |

| AC Voltage | 118.4 V | 117.0 V | 115.7 V | 113.9 V | 112.2 V |

| Power Factor | 0.977 | 0.991 | 0.995 | 0.996 | 0.997 |

| Final Result | Pass | Pass | Pass | Pass | Pass |

The 3R System AK6-600M passed our tests, with efficiency between 80% and 86.2%, which is on par with an entry-level product. At full load, however, this unit didn’t provide 82% minimum efficiency as promised by the 80 Plus Bronze. Unfortunately, it is common for power supplies with this certification level to be unable to deliver this efficiency level at real-world temperatures. The tests to obtain the 80 Plus certification are conducted at 23° C, and efficiency drops with temperature.

Voltage regulation was excellent, with all voltages closer to their nominal values (3% regulation) during all tests, except the -12 V output during test five (at -12.38 V), which was still inside the allowed range. The ATX12V specification states that positive voltages must be within 5% of their nominal values, and negative voltages must be within 10% of their nominal values.

Let’s discuss the ripple and noise levels on the next page.

[nextpage title=”Ripple and Noise Tests”]

Voltages at the power supply outputs must be as “clean” as possible, with no noise or oscillation (also known as “ripple”). The maximum ripple and noise levels allowed are 120 mV for +12 V and -12 V outputs, and 50 mV for +5 V, +3.3 V and +5VSB outputs. All values are peak-to-peak figures. We consider a power supply as being top-notch if it can produce half or less of the maximum allowed ripple and noise levels.

The 3R System AK6-600M provided ripple and noise levels below the maximum allowed, but they were too high when we pulled 600 W for us to consider this unit “flawless.”

| Input | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 |

| +12VA | 21.2 mV | 37.4 mV | 51.4 mV | 59.8 mV | 80.4 mV |

| +12VB | 19.4 mV | 31.6 mV | 44.0 mV | 49.2 mV | 70.2 mV |

| +5 V | 12.6 mV | 12.8 mV | 15.6 mV | 18.2 mV | 20.2 mV |

| +3.3 V | 25.4 mV | 26.4 mV | 30.2 mV | 38.0 mV | 45.4 mV |

| +5VSB | 23.6 mV | 25.4 mV | 28.8 mV | 35.8 mV | 42.2 mV |

| -12 V | 62.4 mV | 78.4 mV | 95.2 mV | 94.4 mV | 113.4 mV |

Below you can see the waveforms of the outputs during test five.

Figure 17: +12VA input from load tester during test five at 603.4 W (80.4 mV)

Figure 17: +12VA input from load tester during test five at 603.4 W (80.4 mV)

Figure 18: +12VB input from load tester during test five at 603.4 W (70.2 mV)

Figure 18: +12VB input from load tester during test five at 603.4 W (70.2 mV)

Figure 19: +5V rail during test five at 603.4 W (20.2 mV)

Figure 19: +5V rail during test five at 603.4 W (20.2 mV)

Figure 20: +3.3 V rail during test five at 603.4 W (45.4 mV)

Figure 20: +3.3 V rail during test five at 603.4 W (45.4 mV)

[nextpage title=”Overload Tests”]

Below you can see the maximum we could pull from this power supply. The objective of this test is to see if the power supply has its protection circuits working properly. This unit passed this test, as we couldn’t pull more than shown in the table below because the power supply would shut down, showing that its protections are present and working well. During this extreme configuration, noise and ripple levels were higher than the maximum allowed at +3.3 V (60 mV), +5VSB (53.6 mV), and -12 V (151.6 mV), and touching the limit at +12VA (107.6 mV) and +12VB (103.2 mV). The +5 V output was below the minimum allowed, at +4.74 V.

| Input | Overload Test |

| +12VA | 28 A (336 W) |

| +12VB | 28 A (336 W) |

| +5 V | 12 A (60 W) |

| +3.3 V | 12 A (39.6 W) |

| +5VSB | 3 A (15 W) |

| -12 V | 0.5 A (6 W) |

| Total | 789.4 W |

| % Max Load | 131.6% |

| Room Temp. | 43.0° C |

| PSU Temp. | 45.0° C |

| AC Power | 1049.0 W |

| Efficiency | 75.3% |

| AC Voltage | 109.2 V |

| Power Factor | 0.998 |

[nextpage title=”Main Specifications”]

The main specifications for the 3R System AK6-600M power supply include:

- Standards: ATX12V 2.3

- Nominal labeled power: 600 W continuous, 700 W peak

- Measured maximum power: 789.4 W at 43° C

- Labeled efficiency: 80 Plus Bronze, 82% minim

um at light (i.e., 20%) and full loads and 85% minimum at typical (i.e., 50%) load - Measured efficiency: Between 80% and 86.2%, at 115 V (nominal, see complete results for actual voltage)

- Active PFC: Yes

- Modular Cabling System: Yes

- Motherboard Power Connectors: One 20/24-pin connector and two ATX12V connectors that together form an EPS12V connector, permanently attached to the power supply

- Video Card Power Connectors: Two six/eight-pin connectors on two cables, modular cabling system

- SATA Power Connectors: Three on one cable, modular cabling system

- Peripheral Power Connectors: Three on one cable, modular cabling system

- Floppy Disk Drive Power Connectors: One

- Protections (as listed by the manufacturer): Over voltage (OVP), under voltage (UVP), over current (OCP), over power (OPP), over temperature (OTP), and short-circuit (SCP) protections

- Are the above protections really available? Yes

- Warranty: NA

- More Information: https://www.3rsys.com

- MSRP in the U.S.: NA

[nextpage title=”Conclusions”]

The 3R System AK6-600M is an AK6-500M with two basic modifications: an electrolytic capacitor with higher capacitance in the primary, and the replacement of one of the +12 V rectifiers with a MOSFET. These small improvements were not enough to increase the performance of this unit. During our tests, efficiency when the unit was delivering 600 W was 80% rather than 82%, as promised by the 80 Plus Bronze certification. As we always explain, the 80 Plus tests are conducted at 23° C; our tests are conducted between 45° C and 50° C. Efficiency drops with temperature. Another issue with this power supply is that it comes with only three SATA power connectors attached to the same cable, which is not enough for a 600 W unit. Noise and ripple levels, although inside specifications, were too high for us to consider this unit “flawless.”

On the positive side, we have voltage regulation, which was excellent, with all positive voltages within three percent of their nominal values, and the maximum efficiency, which peaked at 86 percent.

Based on these findings, it is clear to us that the manufacturer tried to bump a 500 W power supply to 600 W. Even though this unit can really deliver its labeled wattage (in fact, way more than that), the ability of delivering the labeled power is only one of the aspects users must consider when picking a power supply.

Will this power supply work? Yes. Will it damage your computer? No. Are there other better power supplies out there? Definitely. Whether we recommend this unit will depend on its price. If you can find the AK6-600M being sold in your country for less than competing products, it may be an option if its deficiencies don’t bother you.

Leave a Reply